Pollution Prevention

Ask the Expert Question-and-Answer Archiveby George Cushnie

April, 2008Zero Discharge System

Q. I would like to have a zero discharge system for Cu plating line. What would you suggest? I can send the bath sequence.

A. Zero discharge is a relative term. For most metal finishers it means no discharge of wastewater to a sewer system or water course. Inherent in that definition is the generation of a concentrated liquid or solid waste that must be disposed of. There are always some impurities in plating processes that must be removed from the process at some point and these can be troublesome and expensive to deal with.

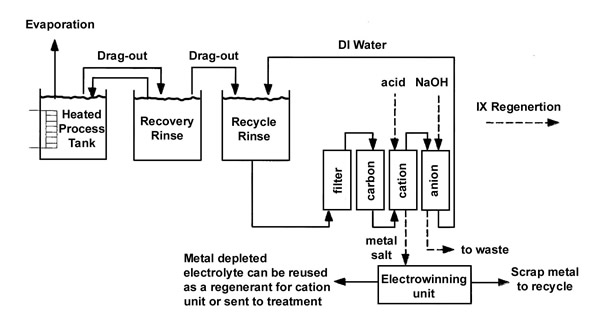

For copper plating, "zero discharge" can be achieved, although it is usually not cost-effective unless there are unusual circumstances, such as very high sewer discharge fees. The most reliable method is a combination of ion exchange (IX) (deionization -- both anion and cation removal) and electrowinning (EW) (see attached figure). A dragout rinse is used to recover the bulk of the copper and therefore allows for installation of smaller and less expensive IX and EW recovery equipment. The ion exchange unit, which is best applied to dilute rinse waters, maintains a low metal concentration in the final rinse. The ion exchange unit concentrates the metal into a regenerant stream and the electrowinning unit removes the metal.

This system will recover the copper, which can be taken to a scrap dealer, and return the rinse water to the plating line. This system will also produce a significant volume of regenerant that will need to be hauled off-site or completely evaporated. Dealing with the regenerant can be very expensive.

In addition to the plating process, you will also need to deal with alkaline cleaning and acid etching rinse waters. There is not much else you can do with these other than evaporation and hauling.

Please let me know if this information is useful.

Regards,

George Cushnie