Hard Chrome Plating Training Course

Section 7—Health and Safety

Health Risks Associated with Exposure to Hexavalent Chromium

There are significant health risks associated with exposure to hexavalent chromium. Plating shop personnel can come in contact with it through:

- direct contact with the skin

- ingestion

- breathing chromic acid droplets dispersed in the plating shop air

In this section, we will review the common ways that chromium can get into and onto us, consider the associated health risks, and discuss how we can reduce or prevent these risks.

Please note that this section is intended as a general learning tool. You will also need training specific to your workplace, covering personal protective equipment, and safety and health procedures.

Federal regulations covering hexavalent chromium exposure in the workplace were published in 2006. Some states have adopted more stringent standards. Consult your state OSHA authority for more information.

Skin Contact

When racks of parts are removed from the chrome plating tank, they will drip chromic acid. More liquid may be trapped in recessed pockets, or underneath the masking materials. This creates an opportunity for the plater to get the chromic acid on his hands, arms, face or any areas of exposed skin. This happens most often when rinsing the part after plating, or when removing the masking materials. If chromic acid gets into a preexisting cut, blister or other open wound, it will slow down the body's healing process, and it will take a long time to heal. Repeated contact with the skin often causes skin ulcers referred to as "chrome sores." These are unsightly and painful, and they heal very slowly. Even occasional contact with chromic acid can cause dermatitis (itchy red rash) or swelling.

Platers should prevent chromic acid from coming in contact with skin. This is easily accomplished using the following items of protective clothing and equipment:

- polyester coveralls provide overall body protection

- platers' gloves protect the hands, and if they are long enough, the forearms as well

- a plater's apron (made from impervious material) protects the entire front of the body

- goggles or a face shield protects the face and eyes

These items should be readily available for you, and you should wear them in any situation where the risk of skin contact exists.

Polyester work clothes are better suited than cotton, because polyester withstands chemical attack from chromic acid much better than cotton fiber. Used work clothes should be kept separated from non-contaminated clothing.* (*Section 1910.1026 of the OSHA hexavalent chromium rule contains specific rules regarding work clothes.)

Ingestion

Small quantities of chromium can be ingested by eating or smoking. This occurs when chromic acid is transferred from a hand or glove to food or a cigarette. Ingestion of chromic acid is serious business. Potential heath effects include:

- Stomach ulcers

- Liver damage

- Kidney damage

- Convulsions

- Death

You can prevent ingestion by this route by following one simple rule – always remove platers' gloves and wash your hands thoroughly before eating or smoking.

Breathing

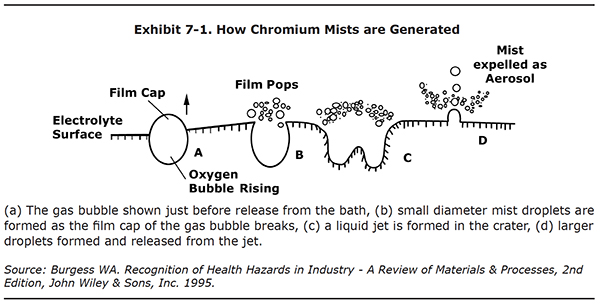

The inhalation of chromic acid mist is a serious concern in hard chrome shops. The main source of this mist is the small gas bubbles which form at the electrodes generated during electroplating (Exhibit 7-1). The bubbles rise to the surface and burst, creating a fine mist above the bath. In addition to process fumes, airborne chromium dust may be generated when adding replenishment chromium trioxide flakes to the chrome plating tank.

Before exhaust ventilation and air pollution control standards were adopted in the U.S., many chrome shops had inadequate ventilation systems that allowed a significant amount of chromic acid mist into the plating room environment. Workers would breathe the airborne chromium for hours during the course of their work shift. Repeated nosebleeds were common symptoms. The nasal septum is the bone and cartilage that separates the left and right nostrils in the nose. With enough exposure to chromic acid mist, ulcers can form on the septum, and holes can form to the point that the plater no longer has separate left and right nostrils.

Less obvious, but even more serious health risks are associated with breathing hexavalent chromium compounds, including cancer of the sinuses or lungs.

Modern, well-designed exhaust ventilation systems are capable of effectively removing nearly all process fumes, thus preventing their release to the plating room atmosphere. This can be verified by testing to ensure that concentrations of chromium in the ambient air are low enough to prevent any health risk. In such an environment, where testing has confirmed that no airborne health risk exists, the plating room personnel usually do not need personal respirators. But if the normal operating environment has not been tested, or if there are special circumstances that might lead to concentrations of chromic acid high enough to present a health risk, then personnel should wear chemical respirators approved for the application and environment.

If respirators are required it is important that an appropriate respirator be chosen to ensure adequate protection. You should also have fit tested and received training on the respirator's capabilities and limitations. Instruction should also include the care and maintenance of the respirators.

A one-time popular method of reducing chromic acid fumes is the addition of small floating polyethylene balls to the plating tank. Vapors escaping the surface of the bath tend to condense on the balls, thereby causing some of the chromic acid mist to return to the bath. However, the balls are only partially effective and can become an annoyance when they get caught on the racks, fixtures and parts being plated.

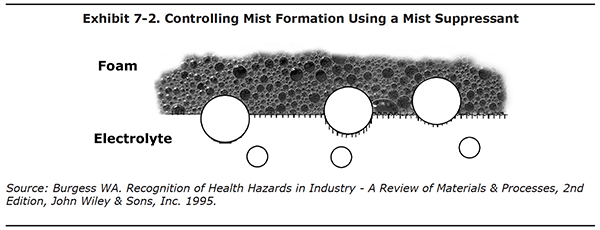

A more effective method of reducing the chromic acid fumes in the plating shop is to use a fume

suppressant. These chemicals are added to the bath and they work either by lowering the surface tension of the bath

or

by creating a foam blanket on the surface of the bath (Exhibit 7-2). Both of which reduce aerosol mist.

Another good method of preventing chromic acid mists in the chrome shop is to install covered tanks. Commercial units are available that only allow the rectifier to operate when the cover is closed. Before the cover is opened, the air inside the tank is evacuated and any chromic acid is filtered out before the air is vented into the shop.

Additional Safety Measures

The following should also be available in the plating shop:

- a shower and eyewash station

- a change of clothing, available to all personnel

In addition, trained "first responders" (those trained in emergencies and decontamination) should be present whenever work is being performed.

Protect Yourself in Case of an Accident

When good operating practices are followed, the likelihood of a serious accident is minimized. However, even the best shop must plan for potential problems so that their effects are minimized.

- Know where the eyewash fountains are in the event of splashes of chemicals into the eyes.

- Know where the emergency showers are.

- Know whom to call if help is needed.

- Make sure electrical control panel padlocks are used for electrical lockout.

- Know the location of emergency stop cables.

Due to the nature of the contaminants found in electroplating, first-aid instruction is essential. The first-aid principles and treatments of greatest importance to the plating industry are as follows:

- Act immediately. Don't be concerned that you might be overreacting to a situation. It is better to overreact than to wait.

- Call 911 or your facility emergency number whenever you think it may be necessary.

- If a person is not breathing, restore breathing and maintain circulation.

- Never administer liquids to an unconscious person.

- If the eyes are chemically affected, immediately flush with plenty of water for at least 15 minutes and seek medical attention.

- If any skin surface is affected or the person's clothing saturated, get the worker to a source of running water immediately (emergency shower, water hose). Dilute the chemical with large amounts of water. Flush clothing thoroughly before attempting to remove it.

- Stop bleeding if serious.